Vista previa de la destilería Mount Gay

El capítulo de Barbados de Modern Caribbean Rum cubre la historia y la elaboración del ron en las cuatro destilerías de Barbados. A continuación, puede leer sobre Mount Gay.

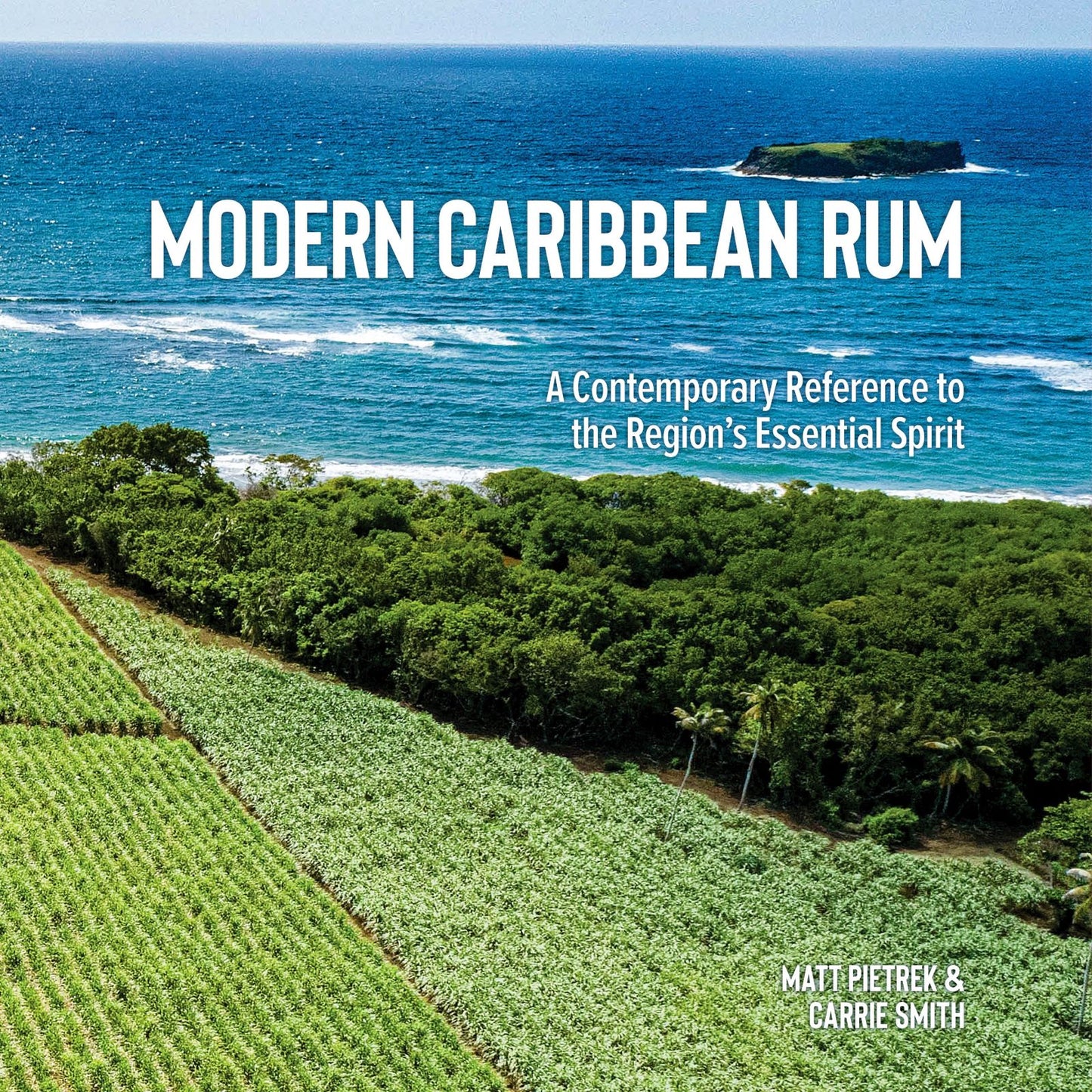

Mount Gay Distillery

Distillation: batch, continuous

Source material: molasses

Major brands: Mount Gay

Estimated LAA/year: 1.5 million

Founded: 1703

Ownership: Remy Cointreau

The story of Caribbean rum cannot be told without referencing Mount Gay. The brand promotes Mount Gay as the oldest continuously operating rum distillery in the world, dating to at least 1703. However, recently discovered records suggest distillation took place on the distillery site even further back. A 1654 indenture (a type of legal document) held by the Barbados Museum and Historical Society refers to the plantation land:

This indenture made the one and twenty day of September in the year of our Lord one thousand six hundred and fifty four

Three coppers one still with mill complete...

The description is shorthand for a typical estate setup: a sugar mill, a boiling house with coppers, and a pot still.

The Mount Gay estate was previously known as Mount Gilboa. In 1747 John Sober purchased it and assigned its day-to-day management duties to Sir John Gay Alleyne, a baronet, politician, and speaker of the Barbados House of Assembly. The Sober family renamed Mount Gilboa to Mount Gay following Alleyne's 1801 death to commemorate his work. They chose Gay rather than Alleyne, as Barbados already had a Mount Alleyne.

The first notable instance of Mount Gay being singled out for its rum was in the late 1890s. Times were tough for sugar estates, and many were abandoned or consolidated. Those who remained focused on exporting sugar and molasses, as rum was no longer profitable. The West India Royal Commission of 1897 takes note of Mount Gay:

I believe a superior rum is made at Mr. Gay s, St. Lucy, which commands a good price. I presume the maker finds it pay?

Answer. Mt. Gay makes a good redistilled rum, and commands at the moment 4d. per gallon more than other distilleries. I have been privately informed that their profit on rum last year was nearly 500L.

Between 1894 and 1896, Mount Gay produced around 23,000 liters of redistilled rum annually. Redistilled meant it passed twice through a batch still.

The Ward Era

In 1908, Aubrey Fitzosbert (AF) Ward acquired Fairfield Plantation and later added Harrison's and Ashton Hall estates to his holdings. In 1918, he purchased the 385-acre Mount Gay plantation in St. Lucy parish for GBP 33,110 (approximately GBP 1.6 million at 2021 prices). Ward later consolidated his plantation holdings under the Fairfield and Mount Gay Ltd. company.

Because of the law that effectively prevented distilleries from selling directly to consumers, Ward and his partner John Hutson created a separate company, Mount Gay Distilleries Ltd., to blend and bottle rum in 1926. Despite its name, Mount Gay Distilleries Ltd. was not a distillery; it bottled and sold Mount Gay branded rum. AF Ward's signature appeared on Mount Gay labels for many years to follow.

The distinction between Mount Gay Distilleries Ltd. (the bottler) and the Rum Refinery of Mount Gay (the distillery) is crucial to understanding Mount Gay's subsequent history. The primary business enterprises of the Ward family between the 1950s and 1970s were:

- Fairfield and Mount Gay Ltd.: Plantation operations, including the distillery in St. Lucy.

- Mount Gay Distilleries Ltd.: Blending and bottling rum in Bridgetown; owner of the Mount Gay brand.

When AF Ward died in 1948, his Fairfield and Mount Gay shares were distributed to many of his approximately fifty A.F. Ward children. Many of his descendants still retain small stakes in that business.

However, Ward's stake in Mount Gay Distilleries Ltd. was inherited by two of his children, Lisle and Darnley Ward, who ran the brand for several more decades. Lisle focused on the rum operations while Darnley handled marketing.

In 1975, Fairfield and Mount Gay Ltd. were split to separate the profitable and unprofitable parts of the business. The sugar business truggled due to falling prices, while the distillery held its own. Following the split, the companies were:

- Fairfield Investments Ltd.: The sugarcane plantations, owned by AF Ward's descendants

- Rum Refinery of Mount Gay: The St. Lucy distillery

- Mount Gay Distilleries Ltd.: The Mount Gay bottling facility and brand

In 1980 Mount Gay Distilleries Ltd. sold a 60 percent stake to their American distributor, Foremost-McKesson, who later sold off its spirits portfolio ( 21 Brands ). In 1989 Remy Martin (now Remy Cointreau) bought 21 Brands. Thus, Remy came to own the Mount Gay brand and bottling facilities, but not the distillery that remained owned primarily by the Ward family.

Darnley and Lisle Ward subsequently passed control to Lisle's son, Llewellyn Louis Ward. Louis retired in the early 1990s, passing control to Carl Ward, one of AF Ward's youngest sons. In 1998, Frank Ward, Jr. joined the family business to become Mount Gay's managing director in 2005.

By the time Frank took the reins, the Rum Refinery was in dire financial straits, and substantial upgrades were needed to keep it operating. However, various shareholders (including certain Ward family members) no longer wanted to invest more money. In 2014, Remy Cointreau purchased majority control of the Rum Refinery of Mount Gay for USD 9.5 million, giving the company complete control over the distillery and brand.

The Last Ward

Before their 2014 acquisition, Remy's contract with the Rum Refinery of Mount Gay did not give Remy exclusive rights to all of the distillery's output. From 2007 onward, Frank Ward, Jr. made some triple distilled rum, i.e., three passes through the pot stills.

Some of this rum went to the Mount Gilboa brand, owned by Ward. Both unaged and aged Mount Gilboa was bottled; the unaged Mount Gilboa is quite rare. Ward later sold some of the triple distilled rum to Velier and Plantation. Velier subsequently released it as the cheekily named Last Ward 2007 and 2009 releases.

The Remy Cointreau Era

Remy Cointreau's investment has continued since buying the Rum Refinery of Mount Gay. In 2014 they purchased the Oxford plantation land adjoining the distillery and acquired the original Mount Gay Plantation land for USD 4.9 million a year later. The acquisitions targeted AF Ward's original cane fields, with the intent of supplying some of the distillery's molasses needs from estate-grown sugarcane.

- Remy has also substantially upgraded the distillery and its equipment, including:

- Recommissioning a 100 percent copper Coffey still last used in 1976

- Replacing five wooden fermenting vats with new French oak vats

- Installing new liquid natural gas boilers/burners

- Restoring a building for use as a visitors'center

- Constructing a sugar mill and factory to make sugar and molasses

Sustainability of operations is an important goal for Mount Gay. The company targets 100 percent sustainable agriculture by 2025, 100 percent sustainable energy by 2028, and carbon neutrality by 2030.

Distillery Operations

For most Barbados guests, a Mount Gay tour means visiting the bottling facility in Bridgetown, which can accommodate busloads of tourists in its theater, restaurant, bar, and gift shop. Visiting the actual distillery was once a rare treat only for industry people. Luckily, a new visitors' center at the distillery opened in 2018, although tours must be booked in advance.

The scenic drive from Bridgetown to St. Lucy soon turns to cane fields as far as the eye can see. Occasionally the Atlantic Ocean peeks into view. A turn off the main road leads 250 meters into the heart of the distillery complex.

The distillery has two separate distillation hubs, each with its own fermenters and stills.

Sugarcane and Molasses

The Oxford plantation lies less than a kilometer from the distillery. The remnants of a stone windmill that once drove cane mill rollers centuries ago are a photogenic highlight. The surrounding cane fields are a sea of green. The resulting molasses from this sugarcane will find its way into the distillery's fermenters.

Mount Gay's cane farming is environmentally aware and utilizes the assistance of the West Indies Central Sugar Cane Breeding Station. Each field grows a single sugarcane varietal and is irrigated naturally via rainfall. The distillery's vinasse is (carefully) applied to the cane fields for fertilization.

Mount Gay has used Barbados Agricultural Management Company (BAMC) to process their estate-grown sugarcane, keeping the resulting molasses separate from other BAMC-made molasses. Once the distillery's onsite sugar mill comes online (estimated for 2022), it will handle all of Mount Gay's sugarcane processing.

Mount Gay's estate molasses has only one sugar extraction, so it is Grade A molasses. While estate-grown molasses fulfills only a fraction of the distillery's needs, it enables single estate releases of rum.

Water Source

Back at the distillery, a trek down a slight slope ends at a well house near a grove of trees. The well's shaft burrows more than three hundred feet into the earth to draw out limestone-filtered water. The distillery is the only one in Barbados with such a setup. The well is constantly monitored for water quality and to avoid over-extraction.

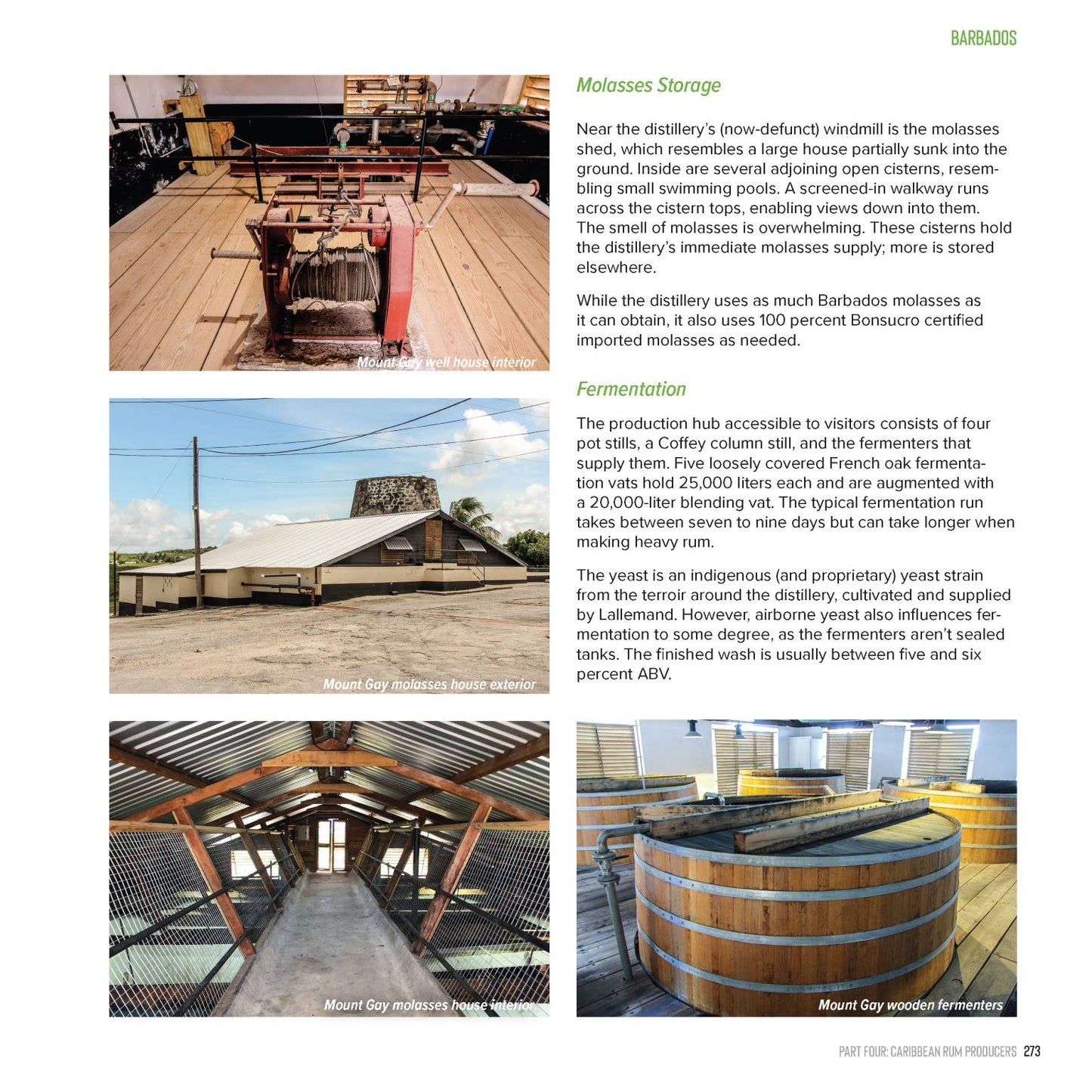

Molasses Storage

Near the distillery's (now-defunct) windmill is the molasses shed, which resembles a large house partially sunk into the ground. Inside are several adjoining open cisterns, resembling small swimming pools. A screened-in walkway runs across the cistern tops, enabling views down into them.

The smell of molasses is overwhelming. These cisterns hold the distillery's immediate molasses supply; more is stored elsewhere.

While the distillery uses as much Barbados molasses as it can obtain, it also uses 100 percent Bonsucro certified imported molasses as needed.

Fermentation

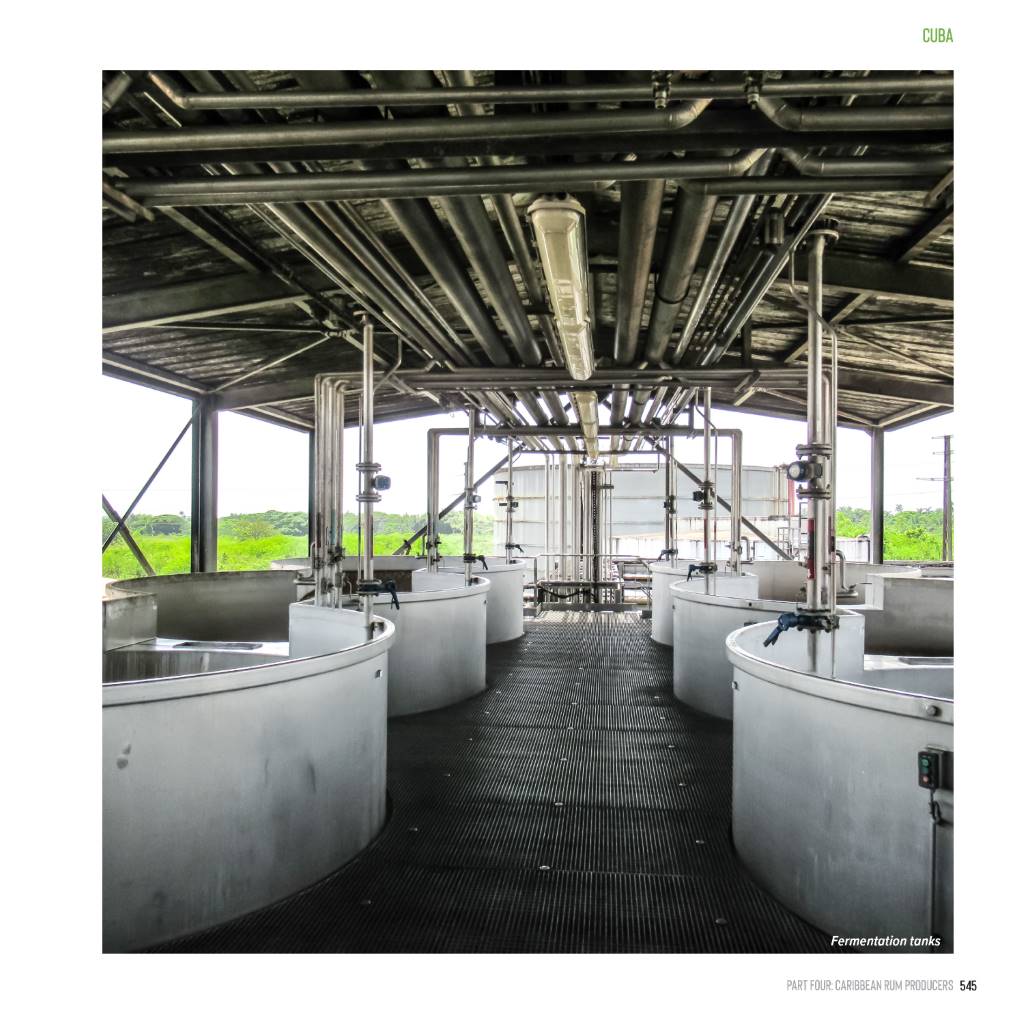

The production hub accessible to visitors consists of four pot stills, a Coffey column still, and the fermenters that supply them. Five loosely covered French oak fermentation vats hold 25,000 liters each and are augmented with a 20,000-liter blending vat. The typical fermentation run takes between seven to nine days but can take longer when making heavy rum.

The yeast is an indigenous (and proprietary) yeast strain from the terroir around the distillery, cultivated and supplied by Lallemand. However, airborne yeast also influences fermentation to some degree, as the fermenters aren t sealed tanks. The finished wash is usually between five and six percent ABV.

Distillation

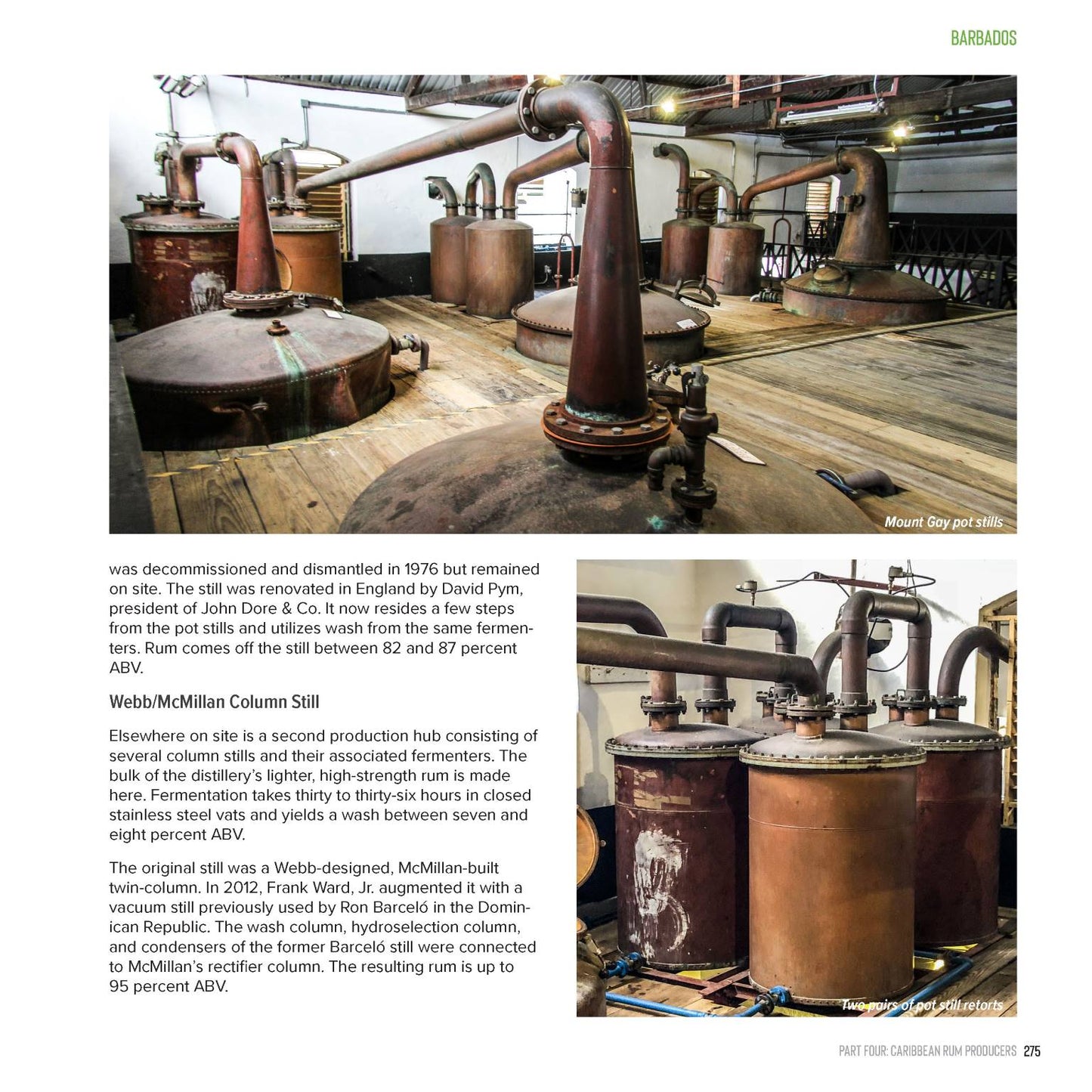

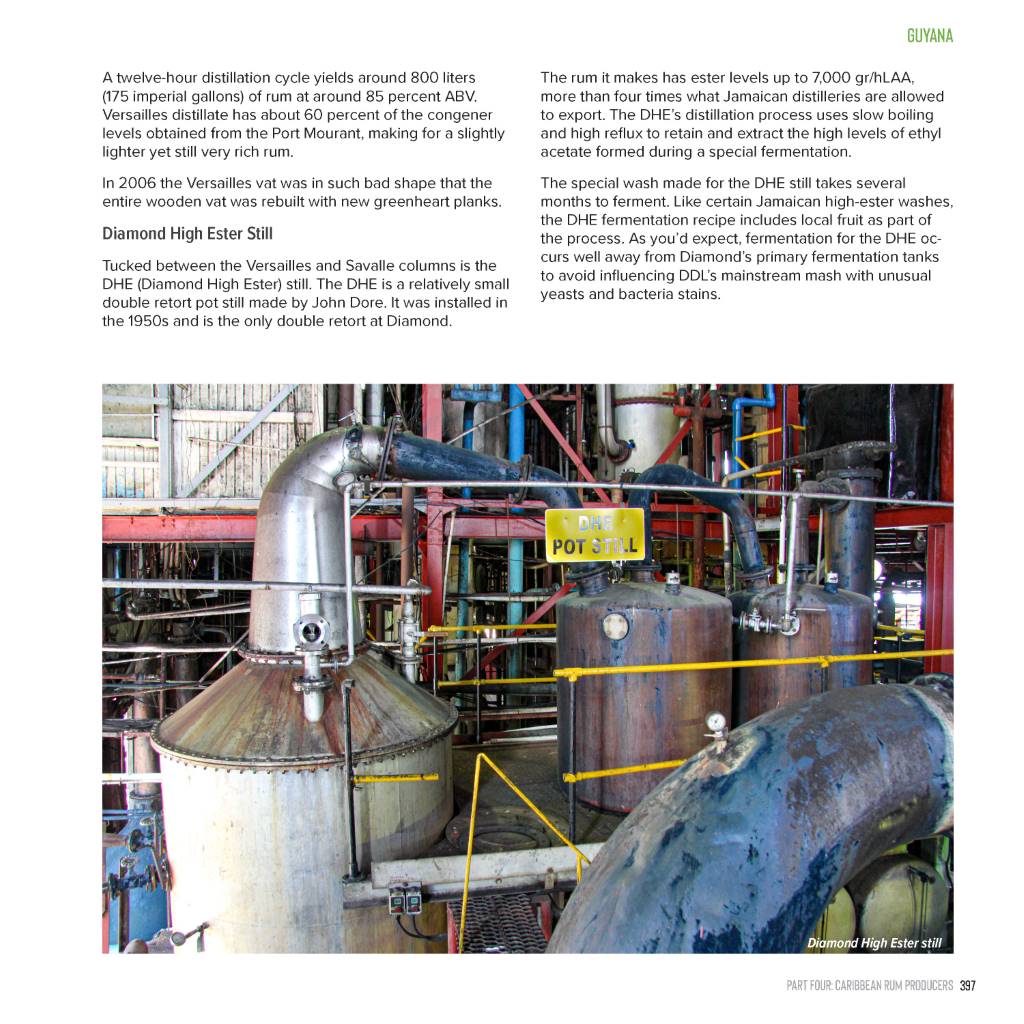

Some distilleries are instantly recognizable from their stills; Mount Gay's quartet of double retorts, aligned in a row within the still house, is one example. The iconic image of the stills is only of their upper portion, however. A raised wooden platform conceals most of the large kettles below.

Mount Gay's pot stills look noticeably different than their counterparts in Jamaica, Barbados, or St. Lucia. These kettle tops are relatively flat, with narrow goosenecks rising from the center. One pair was made in Scotland by McMillan in the 1960s; their kettles hold 4,000 liters, and they make a relatively heavy rum. The other pair of stills were made in the early 2000s in Spain by Fragasa; each kettle holds 6,000 liters and makes a lighter, fruitier distillate relative to the McMillans.

Unlike most Caribbean double retort stills, which fully distill in one pass, Mount Gay's stills use two passes to yield a rum between 73 and 82 percent ABV.

One still is noticeably different from the others due to its exceptionally long lyne arm. It's because the still house is only wide enough to accommodate three kettles in a row. The fourth kettle is placed further back and not aligned with the other three kettles, so needs a much longer lyne arm to reach its retorts.

In 2018, the distillery recommissioned its twin-column, all-copper Coffey still, first installed in the early 1940s; the still was decommissioned and dismantled in 1976 but remained on site. The still was renovated in England by David Pym, president of John Dore & Co. It now resides a few steps from the pot stills and utilizes wash from the same fermenters. Rum comes off the still between 82 and 87 percent ABV.

Webb/McMillan Column Still

Elsewhere on site is a second production hub consisting of several column stills and their associated fermenters. The bulk of the distillery's lighter, high-strength rum is made here. Fermentation takes thirty to thirty-six hours in closed stainless steel vats and yields a wash between seven and eight percent ABV.

The original still was a Webb-designed, McMillan-built twin-column. In 2012, Frank Ward, Jr. augmented it with a vacuum still previously used by Ron Barcel in the Dominican Republic. The wash column, hydroselection column, and condensers of the former Barcelo still were connected to McMillan's rectifier column. The resulting rum is up to 95 percent ABV.

Aging & Blending

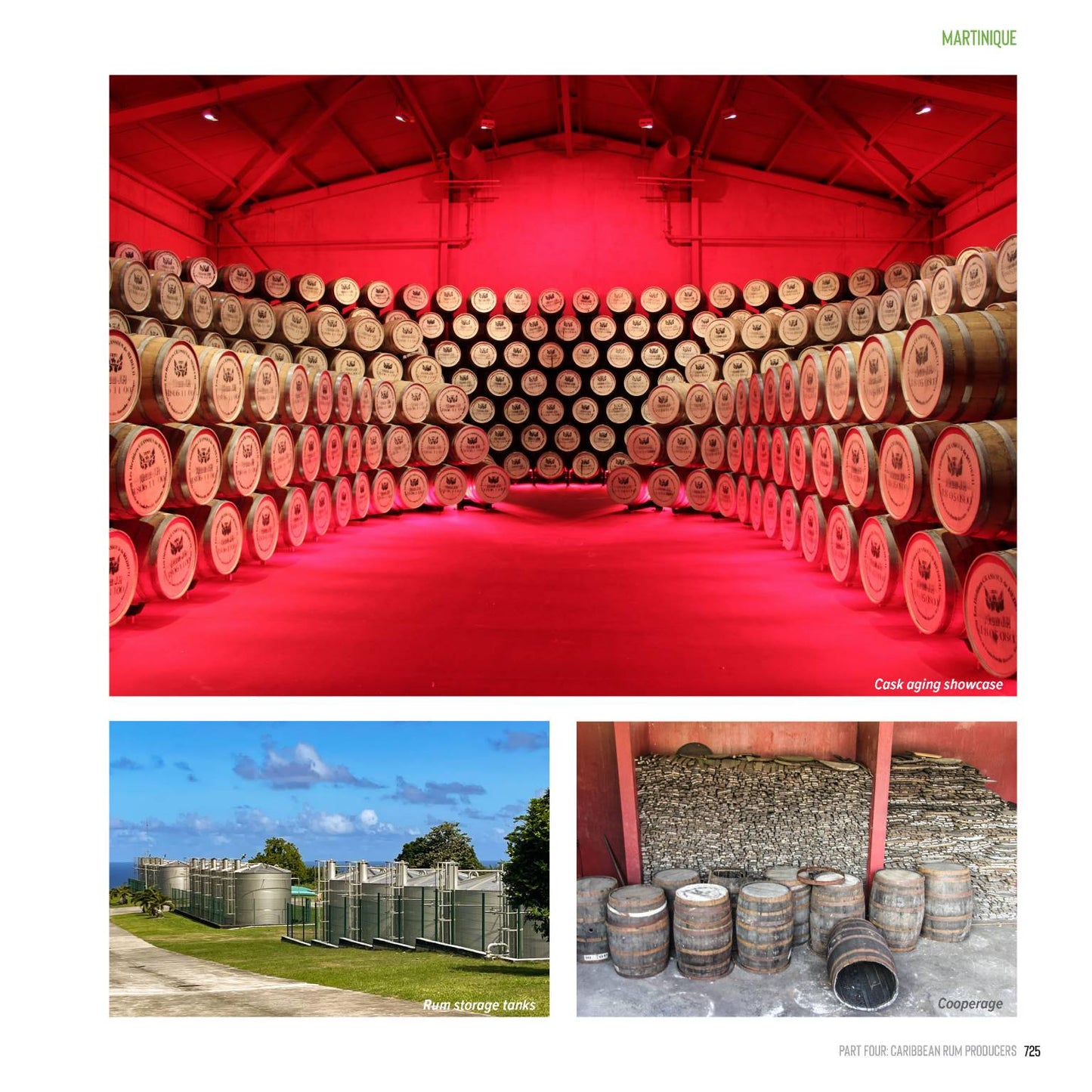

Mount Gay's aging occurs in several squat, cement block buildings topped with pitched roofs. Parts of their outer walls are dappled black from distiller's mold. Currently, around 55,000 casks are aging, and another bond holding 24,000 should be completed by the end of 2022.

A small range of cask types handle most of the aging at Mount Gay:

- Ex-bourbon

- Ex-American whisky (primarily Jack Daniels)

- Ex-cognac (French oak)

In addition, smaller amounts of rum age in research casks such as port, sherry, sauternes, Islay Scotch whisky, and Acacia wood. Periodically, casks of similar rum of the same age are consolidated to reduce the angel's share.

Rum is diluted to 70 percent ABV before casking. Pot and column distilled rums age separately and are later blended to create Mount Gay's core expressions such as Eclipse, Black Barrel, and XO. Final blending and bottling occur at Mount Gay's Bridgetown facility.

Wonk Press

Modern Caribbean Rum